Kawasaki Z1000SX - Service manual > Periodic Maintenance Chart

Kawasaki Z1000SX - Service manual > Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition. The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

#: Service more frequently when operating in severe conditions; dusty, wet,

muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established

here.

Periodic Replacement Parts

#: Service more frequently when operating in severe conditions; dusty, wet,

muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established

here.

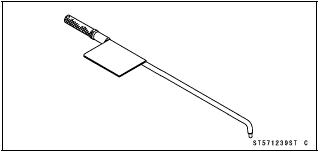

Torque and Locking Agent

The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc.

Letters used in the "Remarks" column mean:

AL: Tighten the two clamp bolts alternately two times to ensure even

tightening torque.

G: Apply grease.

L: Apply a non-permanent locking agent.

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10

: 1)

R: Replacement Parts

S: Follow the specified tightening sequence.

Si: Apply silicone grease (ex. PBC grease).

SS: Apply silicone sealant.

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

Specifications

Special Tools

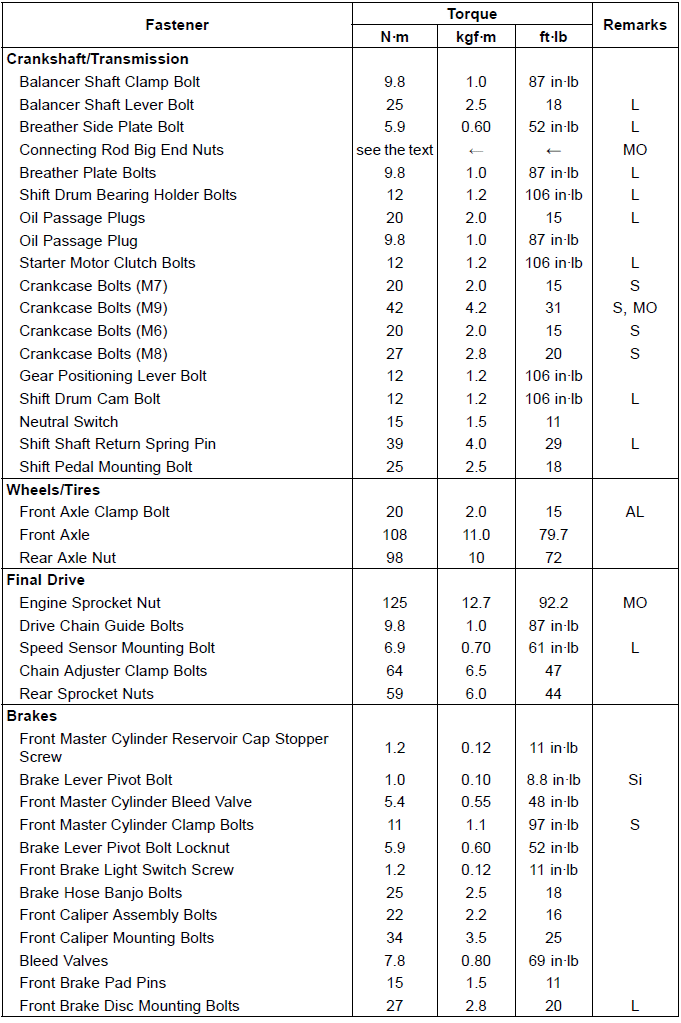

Inside Circlip Pliers: 57001-143

Attachment Jack: 57001-1252

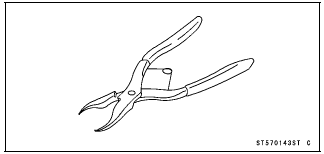

Steering Stem Nut Wrench: 57001-1100

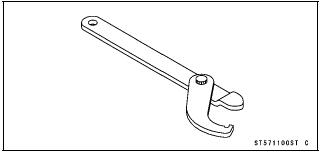

Spark Plug Wrench, Hex 16: 57001-1262

Jack: 57001-1238

Vacuum Gauge: 57001-1369

Pilot Screw Adjuster, A: 57001-1239

Throttle Sensor Setting Adapter: 57001-1538

Oil Filter Wrench: 57001-1249

Fuel Hose: 57001-1607

Jack Attachment: 57001-1608

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07