Kawasaki Z1000SX - Service manual > Intake Air Pressure Sensor #2 (Service Code 16)

Kawasaki Z1000SX - Service manual > Intake Air Pressure Sensor #2 (Service Code 16)

Intake Air Pressure Sensor #2 Removal

NOTICE Never drop the intake air pressure sensor #2 especially on a hard surface. Such a shock to the sensor can damage it.

- Remove the air cleaner housing (see Air Cleaner Housing Removal).

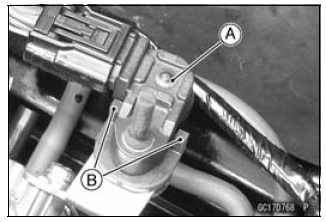

- Disconnect the sensor connector [A].

- Remove the intake air pressure sensor #2 [A] from the rubber damper [B] in the bracket and separate the vacuum hose [C].

Intake Air Pressure Sensor #2 Installation

NOTE

- The intake air pressure sensor #2 is the same part as the intake air pressure sensor #1.

- Installation is the reverse of removal.

- Position the intake air pressure sensor #2 [A] between the projection [B] on the rubber damper.

Intake Air Pressure Sensor #2 Input Voltage Inspection

NOTE

- Be sure the battery is fully charged.

- Turn the ignition switch OFF.

- Remove the air cleaner housing (see Air Cleaner Housing Removal).

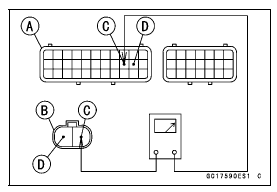

- Disconnect the intake air pressure sensor #2 connector and connect the

harness adapter [A] between these connectors.

[B] Main Harness

[C] Intake Air Pressure Sensor #2

Special Tool - Measuring Adapter: 57001-1700

- Connect a digital meter [D] to the harness adapter leads.

Intake Air Pressure Sensor #2 Input Voltage

Connections to Adapter:

Digital Meter (+) → R (sensor BL) lead

Digital Meter (-) → BK (sensor BR/BK) lead

- Measure the input voltage with the engine stopped and with the connector joined.

- Turn the ignition switch ON.

Input Voltage

Standard: DC 4.75 - 5.25 V

- Turn the ignition switch OFF.

If the reading is within the standard, check the output voltage (see Intake Air Pressure Sensor #2 Output Voltage Inspection).

If the reading is out of the standard, remove the ECU and check the wiring for continuity between main harness connectors.

Special Tool - Hand Tester: 57001-1394

- Disconnect the ECU and sensor connectors.

Wiring Continuity Inspection

ECU Connector [A] ←→

Intake Air Pressure Sensor #2 Connector [B]

BL lead (ECU terminal 5) [C]

BR/BK lead (ECU terminal 33) [D]

If the wiring is good, check the ECU for its ground and power supply (see ECU Power Supply Inspection).

If the ground and power supply are good, replace the ECU (see ECU Removal/Installation).

Intake Air Pressure Sensor #2 Output Voltage Inspection

- Measure the output voltage at the intake air pressure sensor #2 in the

same way as input voltage inspection, note the following.

- Disconnect the intake air pressure sensor #2 connector and connect

the harness adapter [A] between these connectors.

[B] Main Harness

[C] Intake Air Pressure Sensor #2

[D] Digital Meter

- Disconnect the intake air pressure sensor #2 connector and connect

the harness adapter [A] between these connectors.

Special Tool - Measuring Adapter: 57001-1700

Intake Air Pressure Sensor #2 Output Voltage

Connections to Adapter:

Digital Meter (+) → Y (sensor G/W) lead

Digital Meter (-) → BK (sensor BR/BK) lead

- Measure the output voltage with the engine stopped and with the connector joined.

- Turn the ignition switch ON.

Output Voltage

Usable Range:

DC 3.80 - 4.20 V at standard atmospheric pressure (101.32 kPa, 76 cmHg

absolute)

NOTE

- The output voltage changes according to the local atmospheric pressure.

- Turn the ignition switch OFF.

If the reading is out of the usable range, replace the sensor.

If the reading is within the usable range, remove the ECU and check the wiring for continuity between main harness connector.

Special Tool - Hand Tester: 57001-1394

- Disconnect the ECU and sensor connectors.

Wiring Continuity Inspection

ECU Connector [A] ←→

Intake Air Pressure Sensor #2 Connector [B]

G/W lead (ECU terminal 16) [C]

BR/BK lead (ECU terminal 33) [D]

If the wiring is good, check the sensor for various vacuum (see Intake Air Pressure Sensor #1 Output Voltage Inspection).

Intake Air Pressure Sensor #2 Circuit

- ECU

- Intake Air Pressure Sensor #2

Crankshaft Sensor (Service Code 21)

The crankshaft sensor has no power source, and when the engine stops, the crankshaft sensor generates no signals.

Crankshaft Sensor Removal/Installation

- Refer to the Crankshaft Sensor Removal/Installation in the Electrical System chapter.

Crankshaft Sensor Resistance Inspection

- Refer to the Crankshaft Sensor Inspection in the Electrical System

chapter.

If the reading is within the standard, check the peak voltage (see Crankshaft Sensor Peak Voltage Inspection).

Crankshaft Sensor Peak Voltage Inspection

- Refer to the Crankshaft Sensor Peak Voltage Inspection in the Electrical

System chapter.

If the reading is within the standard, remove the ECU and check the wiring for continuity between main harness connectors.

- Disconnect the ECU and sensor connectors.

Wiring Inspection

ECU Connector [A] ←→

Crankshaft Sensor Connector [B]

Y/BK lead (ECU terminal 20) [C]

BK lead (ECU terminal 21) [D]

If the wiring is good, check the ECU for its ground and power supply (see ECU Power Supply Inspection).

If the ground and power supply are good, replace the ECU (see ECU Removal/Installation).

Crankshaft Sensor Circuit

- ECU

- Crankshaft Sensor

See also:

Kawasaki Z1000SX - Service manual > Water Temperature Sensor (Service Code 14)

Kawasaki Z1000SX - Service manual > Water Temperature Sensor (Service Code 14)

Water Temperature Sensor Removal/Installation NOTICE Never drop the water temperature sensor especially on a hard surface. Such a shock to the sensor can damage it. Drain the coolant (see Coolant Change in the Periodic Maintenance chapter). Remove: Left Lower Fairing (see Lower Fairing Removal in the Frame chapter) Connector [A] Water Temperature Sensor [B] Replace the gasket with a new one, and tighten the water temperature sensor.

Kawasaki Z1000SX - Service manual > Speed Sensor (Service Code 24, 25)

Kawasaki Z1000SX - Service manual > Speed Sensor (Service Code 24, 25)

Speed Sensor Removal/Installation Refer to the Speed Sensor Removal/Installation in the Electrical System chapter. Speed Sensor Inspection Refer to the Speed Sensor Inspection in the Electrical System chapter.

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07