Royal Enfield Interceptor 650 - Service manual > General Precautions

Royal Enfield Interceptor 650 - Service manual > General Precautions

Important information and points that need special focus and attention while servicing the motorcycles are highlighted in this service manual as follows:

NOTE Indicates points of particular interest for more efficient and convenient operation.

WARNING Indicates points of particular interest for more efficient and convenient operation.

CAUTION Alerts the technician about potential personal injury hazards.

WARNING

Stop the engine when servicing the fuel system. Do not smoke or allow any open flame or sparks near gasoline. Gasoline is extremely flammable and highly explosive, which could result in serious injury or fatal accidents.

Do not use after-market parts which can adversely affect the performance. Removing or altering factory installed parts can adversely affect performance and could result in serious injury or fatal accidents.

CAUTION

Do not tamper or attempt any modifications to any part of the engine management, fuel injection, ABS brakes, exhaust and evaporative emission systems of the motorcycle as it is against the law and will render the motorcycle unfit and illegal for road use.

Prior to Service

Proper preparation is very important before commencing any maintenance or repair on a motorcycle. This will not only result in an efficient and accurate repair job but will also save time and result in "FIRST TIME RIGHT" and help the customer gain confidence in the technician's capability.

The following points are essential for carrying out maintenance or repairs on a motorcycle correctly:

1. Understand and record customer concerns accurately.

2. Test-ride the motorcycle wherever required to understand the customer concerns accurately.

3. Refer to the past history of maintenance and repairs carried out on the motorcycle.

4. Water-wash and clean the motorcycle.

5. Maintain the work area - cleanliness, lighting, ventilation, etc.

6. Store appropriate general purpose and special tools for carrying out the maintenance.

7. Perform systematic dismantling and reassembly of the aggregates in the motorcycle.

8. Store required spares and consumables for the maintenance.

9. Perform correct inspection and diagnosis of the motorcycle.

10. Test-ride after repairs to ensure that motorcycle is performing correctly.

11. Explain the repairs and maintenance carried out to the customer.

12. Encourage customer to take a test-ride so as to gain confidence that the repairs have been carried out correctly and to his satisfaction.

Customer Complaints

Discuss with customer to clearly understand their concerns and issues on the motorcycle. Create a job card detailing all the complaints mentioned.

Test-Ride

Do a test ride wherever required to reconfirm issues mentioned by customer. This will also help to identify other issues if any.

Service Records

Check the service records.

Clean Work Area

Ensure the work space is clean and adequately ventilated fresh air.

Cleaning

Cleaning before Dismantling and Inspection

Water-wash and clean the motorcycle for a thorough inspection to uncover any visual damages such as breakages, leaks, misalignments, etc., and to clearly understand the issues raised by the customer.

Clean the motorcycle thoroughly before disassembly to avoid dirt or other foreign materials entering into sealed areas as it can cause excessive wear and damage to the parts.

General and Special Tools

All general and special tools required for servicing are listed in the respective section of this service manual. Ensure that you have all the required tools for servicing. Place tools handy before beginning the service or maintenance.

Special Tools

A list of special tools required for the dismantling and assembling of parts has been provided in each section.

Ensure that only Royal Enfield recommended special tools are used wherever mentioned. Dismantling or assembling without the use of special tools may cause severe, irreparable damage to parts.

Storing Tools

After completing the job, ensure that all tools are cleaned and kept back in their designated place, so that they do not rust and can be easily found the next time.

Tool Usage and Safety

Use eye protection equipment when performing any task using air-operated tools.

Pneumatic tools should be used only for removal, and not for tightening.

Ratchets and Extension

Use an extension on a ratchet's handle or power handle at suitable places.

Torque wrenches should always be used only for tightening fasteners to their recommended torque.

Once you hear the click sound, stop tightening and remove the torque wrench from the fastener. Do not tighten further as it will cause damage to torque wrench and fastener.

Hammers and Mallets

Use eye protection equipment and gloves while using a hammer.

Use a hammer or mallet that is suitable for the job.

Use only a plastic mallet to remove or assemble delicate parts like Oil seals/dowels/bushes, especially in the engine. DO NOT use a metal hammer as it will cause damage to the parts.

Screwdrivers

Use the right type and size of screwdriver at the right places.

Do not use a screwdriver for punching, chiseling or scraping, or as a lever to lift another object.

Use Ramp

Royal Enfield recommends the use of a suitable ramp to hold the motorcycle vertically in a convenient position for easy repairs.

Prior to Disassembly

Always ensure ignition switch and stop switch are in OFF position before dismantling any aggregate on the motorcycle.

Always drain engine oil (in warm condition) whenever servicing any part of the engine/oil cooler.

Always drain fuel from the fuel tank whenever it is removed from the frame.

Always disconnect battery terminals whenever servicing the engine management system, ABS and/or any electrical wiring.

Disassembly/Assembly Sequence

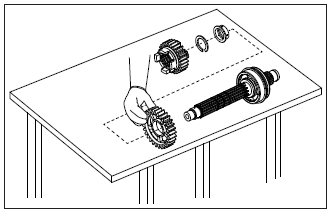

Follow the disassembling and assembling sequence as given in the respective sections of this manual.

In most cases assembly order is the reverse of disassembly. However, please follow the sequence provided in this service manual. If correct sequence is not followed, parts can be damaged.

Removal of Bearings and Seals and fitting them in place

While removing bearings and seals, use correct tools mentioned in the relevant sections. Do not use excess force as it may damage parts. Similarly, while pressing bearings and seals in place lubricate them, use correct tools and visually examine if they are fitted in proper place. Bearings or seals should not be loose in the casing. Use of wrong tools, too much hammering or application of extra force may lead to damage of the bearings and seals.

Lubrication

During assembly, ensure that all rotating and/or sliding parts are lubricated to minimize wear and tear during initial operation. Use Royal Enfield recommended oil and lubricants only. All brake system parts should be cleaned and lubricated with recommended brake fluid only (e.g., piston, MC, etc.).

Tightening Sequence and Torque

The correct tightening sequence and torque has been provided in various sections of this service manual.

Incorrect sequence or wrong torque will cause serious damage to parts.

Battery Disconnection and Connection

When required, disconnect the battery cables from the battery. Disconnect the ground negative (−) terminal first and then positive (+) terminal to avoid short circuit. While connecting, first connect the positive (+) and then the negative (−) terminals.

Electrical Connectors

Ensure that lock is released in the connectors before disconnecting or connecting electrical connectors.

Excessive force to pull out connectors without releasing the lock may damage the connector.

See also:

Royal Enfield Interceptor 650 - Service manual > General Information

Royal Enfield Interceptor 650 - Service manual > General Information

About this Manual This service manual has been created primarily for use by a technically competent and trained service personnel to Get familiarized and understand the construction of various aggregates of motorcycles. Assist in carrying out the correct and factory-approved service and overhauling procedures of the motorcycles.

Royal Enfield Interceptor 650 - Service manual > Safety

Royal Enfield Interceptor 650 - Service manual > Safety

Ignition System Ignition system produces high voltage. When working on any ignition system with the engine running, always keep your hands away from the spark plug wires.

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07