Kawasaki Z1000SX - Service manual > Electrical System

Kawasaki Z1000SX - Service manual > Electrical System

Lights and Switches Operation Inspection

First Step

- Turn on the ignition switch.

- The following lights should go on according to below table.

If the light does not go on, inspect or replace the following item.

Battery (see Charging Condition Inspection in the Electrical System chapter)

Main Fuse 30 A and Taillight Fuse 10 A (see Fuse Inspection in the Electrical System chapter)

Applicable Bulb (see Wiring Diagram in the Electrical System chapter)

Meter Unit for Meter Panel LCD (see Electronic Combination Meter Unit Inspection in the Electrical System chapter)

Meter Unit for Neutral Indicator Light (LED) (see Meter Unit Inspection in the Electrical System chapter)

Meter Unit for Warning Indicator Light (LED) (see Meter Unit Inspection in the Electrical System chapter)

ECU (see ECU Power Supply Inspection in the Fuel System (DFI) chapter)

Ignition Switch (see Switch Inspection in the Electrical System chapter)

Neutral Switch (see Switch Inspection in the Electrical System chapter)

Harness (see Wiring Inspection in the Electrical System chapter)

ABS Indicator Light (LED) (ABS Equipped Models) (see ABS Indicator Light (LED) Inspection in the Brakes chapter)

- Turn off the ignition switch.

- The all lights should go off.

If the light does not go off, replace the ignition switch.

Second Step

- Turn the ignition switch to P (Park) position.

- The city light, taillight and license plate light should go on.

If the light does not go on, inspect or replace the following item.

Ignition Switch (see Switch Inspection in the Electrical System chapter)

Third Step

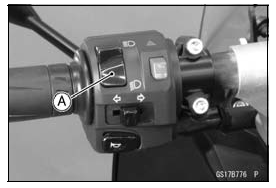

- Turn on the turn signal switch [A] (left or right position).

- The left or right turn signal lights [B] (front and rear) according to the switch position should flash.

- The turn signal indicator light (LED) [C] in the meter unit should flash.

- If the each light does not flash, inspect or replace the following item.

Turn Signal Light Bulb (see Turn Signal Light Bulb Replacement in the Electrical System chapter)

Meter Unit for Turn Signal Indicator Light (LED) (see Meter Unit Inspection in the Electrical System chapter)

Turn Signal Relay Fuse 10 A (see Fuse Inspection in the Electrical System chapter)

Turn Signal Switch (see Switch Inspection in the Electrical System chapter)

Turn Signal Relay (see Turn Signal Relay Inspection in the Electrical System chapter)

Harness (see Wiring Inspection in the Electrical System chapter)

- Push the turn signal switch.

- The turn signal lights and indicator light (LED) should go off.

If the light does not go off, inspect or replace the following item.

Turn Signal Switch (see Switch Inspection in the Electrical System chapter)

Fourth Step

- Set the dimmer switch [A] to low beam position.

- Start the engine.

- The low beam headlight should go on.

If the low beam headlight does not go on, inspect or replace the following item.

Headlight Low Beam Bulb (see Headlight Bulb Replacement in the Electrical System chapter)

Headlight Fuse 10 A (see Fuse Inspection in the Electrical System chapter)

Dimmer Switch (see Switch Inspection in the Electrical System chapter)

Headlight Relay in Relay Box (see Relay Circuit Inspection in the Electrical System chapter)

Harness (see Wiring Inspection in the Electrical System chapter)

- Set the dimmer switch to high beam position.

- The low beam [A] and high beam [B] headlights should go on.

- The high beam indicator light (LED) [C] should go on.

If the high beam headlight and/or high beam indicator light (LED) does not go on, inspect or replace the following item.

Headlight High Beam Bulb (see Headlight Bulb Replacement in the Electrical System chapter)

Meter Unit for High Beam Indicator Light (LED) (see Meter Unit Inspection in the Electrical System chapter)

Dimmer Switch (see Switch Inspection in the Electrical System chapter)

- Turn off the engine stop switch.

- The low beam and high beam headlights should stay going on.

If the headlights and high beam indicator light (LED) does go off, inspect or replace the following item.

Headlight Relay in Relay Box (see Relay Circuit Inspection in the Electrical System chapter)

- Turn off the ignition switch.

- The headlights and high beam indicator light (LED) should go off.

Headlight Aiming Inspection

- Inspect the headlight beam for aiming.

If the headlight beam is off the point, adjust the headlight aiming.

Headlight Beam Horizontal Adjustment

- Remove the meter cover (see Upper Fairing Removal in the Frame chapter.)

- Turn the horizontal adjuster [A] in both headlights with the screwdriver

in or out until the beam points straight ahead.

If the headlight beam points too low or high, adjust the vertical beam.

Headlight Beam Vertical Adjustment

- Turn the vertical adjuster [B] in both headlights in or out to adjust the headlight vertically.

NOTE

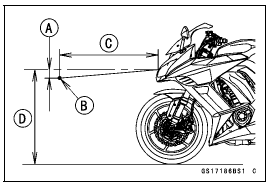

- On high beam, the brightest points should be slightly below horizontal with the motorcycle on its wheels and the rider seated. Adjust the headlight to the proper angle according to local regulations.

NOTE

- For US model, the proper angle is 0.4 degrees below horizontal. This is 50 mm (2 in.) drop at 7.6 m (25 ft) measured from the center of the headlight with the motorcycle on its wheels and the rider seated.

50 mm (2 in.) [A]

Center of Brightest Spot [B]

7.6 m (25 ft) [C]

Height of Headlight Center [D]

Sidestand Switch Operation Inspection

- Inspect the sidestand switch [A] operation accordance to the following table.

Sidestand Switch Operation

If the sidestand switch operation does not work, inspect or replace the following item.

Battery (see Charging Condition Inspection in the Electrical System chapter)

Main Fuse 30 A (see Fuse Inspection in the Electrical System chapter)

Ignition Fuse 15 A (see Fuse Inspection in the Electrical System chapter)

Ignition Switch (see Switch Inspection in the Electrical System chapter)

Sidestand Switch (see Switch Inspection in the Electrical System chapter)

Engine Stop Switch (see Switch Inspection in the Electrical System chapter)

Starter Button (see Switch Inspection in the Electrical System chapter)

Neutral Switch (see Switch Inspection in the Electrical System chapter)

Starter Relay (see Starter Relay Inspection in the Electrical System chapter)

Relay Box (see Relay Circuit Inspection in the Electrical System chapter)

Harness (see Wiring Inspection in the Electrical System chapter)If the all parts are good condition, replace the ECU (see ECU Removal/Installation in the Fuel System (DFI) chapter).

Engine Stop Switch Operation Inspection

First Step

- Turn on the ignition switch.

- Set the neutral position.

- Turn the engine stop switch to stop position [A].

- Push the starter button.

- The engine does not start.

If the engine starts, inspect or replace the following item.

Engine Stop Switch (see Switch Inspection in the Electrical System chapter)

Second Step

- Turn on the ignition switch.

- Set the neutral position.

- Turn the engine stop switch to run position [A].

- Push the starter button and run the engine.

- Turn the engine stop switch to stop position.

- Immediately the engine should be stop.

If the engine does not stop, inspect or replace the following item.

Engine Stop Switch (see Switch Inspection in the Electrical System chapter)

See also:

Kawasaki Z1000SX - Service manual > Steering

Kawasaki Z1000SX - Service manual > Steering

Steering Play Inspection Remove the lower fairing (see Lower Fairing Removal in the Frame chapter). Raise the front wheel off the ground with the jack (see Front Wheel Removal in the Wheels/Tires chapter). With the front wheel pointing straight ahead, alternately tap each end of the handlebar. The front wheel should swing fully left and right from the force of gravity until the fork hits the stop.

Kawasaki Z1000SX - Service manual > Others

Kawasaki Z1000SX - Service manual > Others

Chassis Parts Lubrication Before lubricating each part, clean off any rusty spots with rust remover and wipe off any grease, oil, dirt, or grime. Lubricate the points listed below with indicated lubricant.

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07